Wythenshawe Forum

Bauder Total Roof System (BTRS) with BauderSOLAR F

Synopsis

Hosting a variety of retail, leisure and medical facilities, Wythanshawe Forum is a central hub for the local people. The Stone Roses, Lulu and Hot Chocolate have all showcased their tuneful talents within this historic community building, which is located in a city well-known for its musical pedigree. The thriving hub equally acts as a main transport terminus in Manchester with the Metro-link and bus services operating from this site, connecting Wythenshawe to the rest of Manchester and the North-West alike.

As an important community asset, Manchester City Council decided that for the centre to remain fully fit for purpose, a full large-scale re-rooing project would help to protect the building’s legacy for many years to come. The aging seventies roof was originally built up from Asphalt and limestone chippings, and in the late eighties it was decided that it should be overlaid with a full metal profile flat to pitched conversion. It was only within the past 10 years that the building began to suffer from various severe leaks, causing disruption and safety issues to the building’s users.

Bauder Building Board

|

Project:

|

Wythenshawe Forum

|

|

Location:

|

Manchester

|

|

Project type:

|

Refurbishment

|

|

Roof area:

|

5693m2

|

|

Specifier:

|

Manchester City Council

|

|

Approved contractor:

|

LRL Roofing Solutions Ltd

|

|

Main contractor:

|

F Parkinson Ltd

|

|

Solar PV installer:

|

Absolute Solar and Wind Ltd

|

The specification

This project entailed the installation of three separate roofing systems, primarily focusing around the Bauder BTRS Flatboard and Tapered System.

Products applied

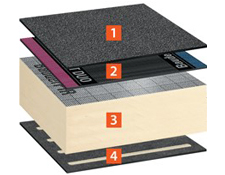

The build-up of the central system consisted of four layers. The first layer was the BauderTEC KSD FBS sheet which was directly applied to the concrete roof deck. The material is tear resistant, aluminium lined and self-adhesive, which acted as the air and vapour control layer for the roof.

The second layer installed was the Bauder PIR FA-TE insulation which is faced on both sides with aluminium foil. This was bonded together with an adhesive to create a strong union and provided the building with greater energy efficiency by thermally upgrading to meet the current building regulations.

Thirdly, the BauderTEC KSA DUO underlay was applied precisely on top of the insulation layer with self-adhesive elastomeric bitumen, bonding itself tightly to the build-up.

Thirdly, the BauderTEC KSA DUO underlay was applied precisely on top of the insulation layer with self-adhesive elastomeric bitumen, bonding itself tightly to the build-up.

To complete the roofing system, a Bauder K5K cap sheet was torch applied by our experienced workforce, providing lasting watertight coverage. This waterproofing system has a service life in excess of 35 years as certified from the BBA. To work towards achieving carbon emmission reduction goals, it was decided to incorporate a solar array on the roof with Bauder's non-penetrative BauderSOLAR system.

Further to this system, we additionally installed a Bauder Thermofol Single Ply roofing system to the swimming pool area. A Bauder cold applied liquid system was also used to repair the areas that were diffcult to reach and where liquid was the only practical solution.

Project challenges

Transport liaison became a major factor throughout the project due to the centre’s location in relation to the transport terminus and airport.

Since it was planned for the crane to be located at the bus stop, the installers had to ensure that works caused minimal disruption to the transport network. Working in conjunction with Transport for Greater Manchester and providing dates in advance, only a single bus stop was closed whilst the crane was in operation and no delays were caused to the bus services that operated from this location.

Due to the building’s proximity to Manchester Airport the height of the crane had to be considered with regard to the restrictions imposed by aerospace law. LRL worked closely with the airport to obtain the relevant permits to enable the works

The result

Bauder approved contractors LRL Roofing Solutions carried out quality installation at the forum, displaying contientious and skilled workmanship. The communication between the Contracts Managers, the client, and the operatives ensured a safe installation despite the number of unforseen challenges that arose.

By working collaboratively we were able to:

- Deliver additional cost savings to the client by specifiying an alternative Bauder system for the swimming pool area.

- Quickly find solutions to damage to the structure of the building, discovered only one the strip had begun.

- Minimise disruption by working out of hours.

- Keep the site open safely during the pandemic thanks to the swift introdution of COVID safe measure such as COVID marshalls to keep the public and the workforce safe.

Despite all the challenges experienced, this project was delivered on time, to budget, and to an exceptionally high standard.

System installed

Bauder Total Roof System (BTRS)

|

1 Bauder K5K

|

A heavy duty, torch-applied SBS elastomeric bitumen capping sheet, featuring a spunbond polyester reinforcement to allow the finished product to cope with structural movement without fracture. The mineral finish provides protection against UV degradation.

|

|

2 BauderTEC KSA DUO 35

|

A technically advanced self-adhesive SBS elastomeric bitumen underlayer with “DUO” lap technology to ensure thorough sealing of lap joints, even in lower temperatures.

|

|

3 BauderPIR FA-TE

|

An efficient PIR insulation board with aluminium foil facing on both sides. The top facing features a printed grid pattern to aid site cutting. It is lightweight and has zero ozone depletion potential.

|

|

4 BauderTEC KSD FBS

|

A self-adhesive SBS elastomeric bitumen air & vapour control layer, with a mica finish.

|

BauderSOLAR PV System

A single source solution for integrated design of waterproofing and PV. This lightweight system involves a risk-free, zero penetration installation, and weighs just 9-12.5kg/sqm. The panels are designed to create a 12º angle for optimum output.

PV contractors, Absolute Solar and Wind Ltd, installed 365 JA 410w panels to give a system size of 150kWp.