Sustainability: managing our impacts

The Bauder group is totally committed to reducing the impact our business has on the environment. Our goal is to ensure we pass to future generations an intact ecological, social and economic company.

Sustainability Brochure

Carbon Reduction, Energy and Waste Management Policy Statement ►

Organisational Carbon Footprint Statement – January 2023 ►

Environmental Product Declarations, Certification and Standards ►

Recycled Content and Recycling Our Products ►

Manufacturing

As a company, we aim to manufacture the highest quality flat roof systems, which offer the longest service life to provide lower whole life costs. By continually focusing on improving manufacturing processes for all of our products.

Operation of our production plants

Our manufacturing plants use closed rotation cooling systems which dramatically reduce water consumption and avoid environmental pollution. Over a five year period we have successfully reduced the energy consumption for the manufacture of PIR insulation by 20% and is a reflection of our ISO 50001 Energy Management accreditation. This is good for the business, good for clients and good for the environment.

Packaging and site waste

On site, we work closely with recycling specialists to reduce rubbish going to landfill. As an example, on a large local authority refurbishment scheme we were instrumental in successfully achieving recycling targets by diverting and reducing the volume of waste to landfill.

Effective roof insulation

It has long been recognised that the insulation of a building is essential to improve thermal performance and reduce the carbon emissions associated with heating buildings, in addition this improves quality of life and increases productivity through better working conditions.

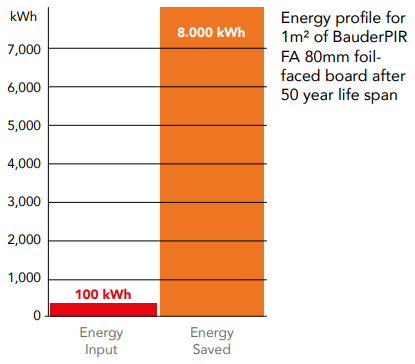

The embodied energy of our rigid polyurethane PIR insulation accounts for as little as 4% of the energy the board can save during its serviceable life. With buildings accounting for 50% of the energy consumption in Europe, the inclusion of insulation when installing new or refurbished roofs plays a significant part in reducing CO2 emissions.