Paxman Avenue Secondary School

Bauderflex bituminous waterproofing system with Euroglaze rooflights

Synopsis

Paxman Avenue Secondary School is a new build project situated in Colchester, Essex. The school opened its doors for the first time in September 2019 welcoming 180 year 7 students. It is expected that the school will eventually hold 900 pupils by 2023.

Paxman Avenue Secondary School

Paxman Avenue Secondary School

Paxman Avenue Secondary School

Paxman Avenue Secondary School

Paxman Avenue Secondary School

Paxman Avenue Secondary School

Bauder Building Board

| Project: |

Paxman Avenue Secondary School |

| Location: |

Colchester, Essex |

| Project type: |

New build |

| Roof size: |

2500m² |

| Architect: |

Concertus Design & Property Consultants |

| Main contractor: |

Barnes Construction |

| Approved contractor: |

G.R.M Roofing Company Ltd |

The specification

The main contractor, Barnes Construction, was looking for a durable, cost effective roof with longevity, and wanted a waterproofing system which included a comprehensive guarantee with great service and full support from the supplier, and so Bauder’s bituminous system, Bauderflex, was specified. Rooflights were also specified to increase natural light into the building.

Bauder’s Rainwater Calculation Software was also used to perform calculations in accordance with BS EN 12056-3:2000 based upon provided data relating to the building’s dimensions, geographical location and the flow rate performance of the selected Bauder rainwater outlet product. This helped to determine the total number of outlets needed for the roof.

Products applied

Bauderflex

A reinforced bituminous membrane system with a choice of self-adhesive and torch-applied membranes that are resistant to high levels of structural and thermal movement.

Bauder Euroglaze rooflights

These rooflights are made to order and the size can therefore be tailor made to fit any roof aperture, with many ventilation and glazing options are available to meet the demands of any type of project.

The result

The client was supported by the Bauder Area Technical Manager, Andy Leggett, from start to finish with help being provided on the design element of the project, and the Bauder approved contractors, G.R.M Roofing Company Ltd, were supported by Bauder site technicians throughout the installation.

System installed

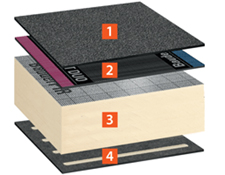

Bauderflex

| 1 BauderFLEX K4E |

A high performance, torch-applied SBS elastomeric bitumen capping sheet. The product features a spunbond polyester reinforcement to allow the finished product to cope with structural movement without fracture, and a mineral finish to provide protection against UV degradation. |

| 2 BauderTEC Sprint DUO |

A technically advanced self-adhesive SBS elastomeric bitumen underlayer with “DUO” lap technology to ensure thorough sealing of lap joints, even in lower temperatures. The product features a glass fleece reinforcement for strength and stability, and benefits from a cleaner, safer and faster installation than traditional torch-applied membranes. |

| 3 BauderPIR FA-TE |

An efficient flatboard PIR insulation board with aluminium foil facing on both sides for optimum thermal capability. |

| 4 BauderTEC KSD FBS |

A technically advanced, robust, self-adhesive SBS elastomeric bitumen air & vapour control layer, with a mica finished upper surface to allow easy bonding of insulation using the specified insulation adhesive. One side lap features an 80mm wide glass fleece along the underside, and a 100mm laminated strip above, with the other side lap having a thermofusible film on the top surface. This arrangement ensures that laps are heat sealed using hot air or gas torch as appropriate to extrude a bitumen bead, thus ensuring waterproofing integrity. |