Risk-Free PV Installation

The distinctive element of the BauderSOLAR system is in the installation of the scheme, which does not require any penetration of the waterproofing or roof deck, even in a non-ballasted arrangement.

This unique installation method sets the system ahead of others and safeguards the integrity of the waterproofing and roof deck; additionally the attachment of the components is very stable so that even in extreme weather the entire array is secure on the roof. Any minor movement of the panels, which is generally created by wind uplift, is easily tolerated and does not affect the fixings, or waterproofing system.

Installing PV on flat roofs

The innovative element of our lightweight PV energy system is the pre-fabricated Bauder membrane sleeves which slip over the mounting plates and are welded into position, anchoring the plates to the surface of the Bauder waterproofing system. Once this is completed, the rest of the PV installation is simply locked into place without any requirement for tools or sharp fixings.

The attachment of the mounting components is very stable so that even in extreme weather the entire array is secure on the roof. Any minor movement of the panels, which is generally created by wind uplift, is easily tolerated and does not affect the fixings, or waterproofing system. The substructure base units are designed to create a 12° angle on to which each PV module is secured; this allows for optimum energy generation per square metre across the roof area.

Installation Process

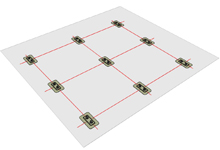

1. Positioning the baseplates

The baseplates are plotted and measured out to ensure correct positioning according to the array design.

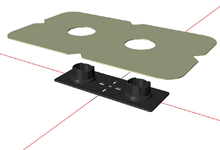

2. Attaching to roof surface

The waterproofing membrane sleeves are placed over each of the baseplates and welded into position. The large attachment footprint is very stable and the entire array is secure on the roof even in extreme weather.

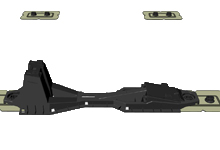

3. Installing the substructures

The substructures are positioned over the mounting plates and locked into place. The distance between the module rows is always 1450 mm due to the fixed length of the substructures.

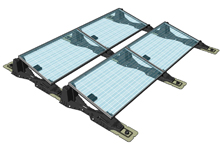

4. Placement of the PV modules

The PV modules are placed on to the substructure mounting system and secured using a tool free fixing method.